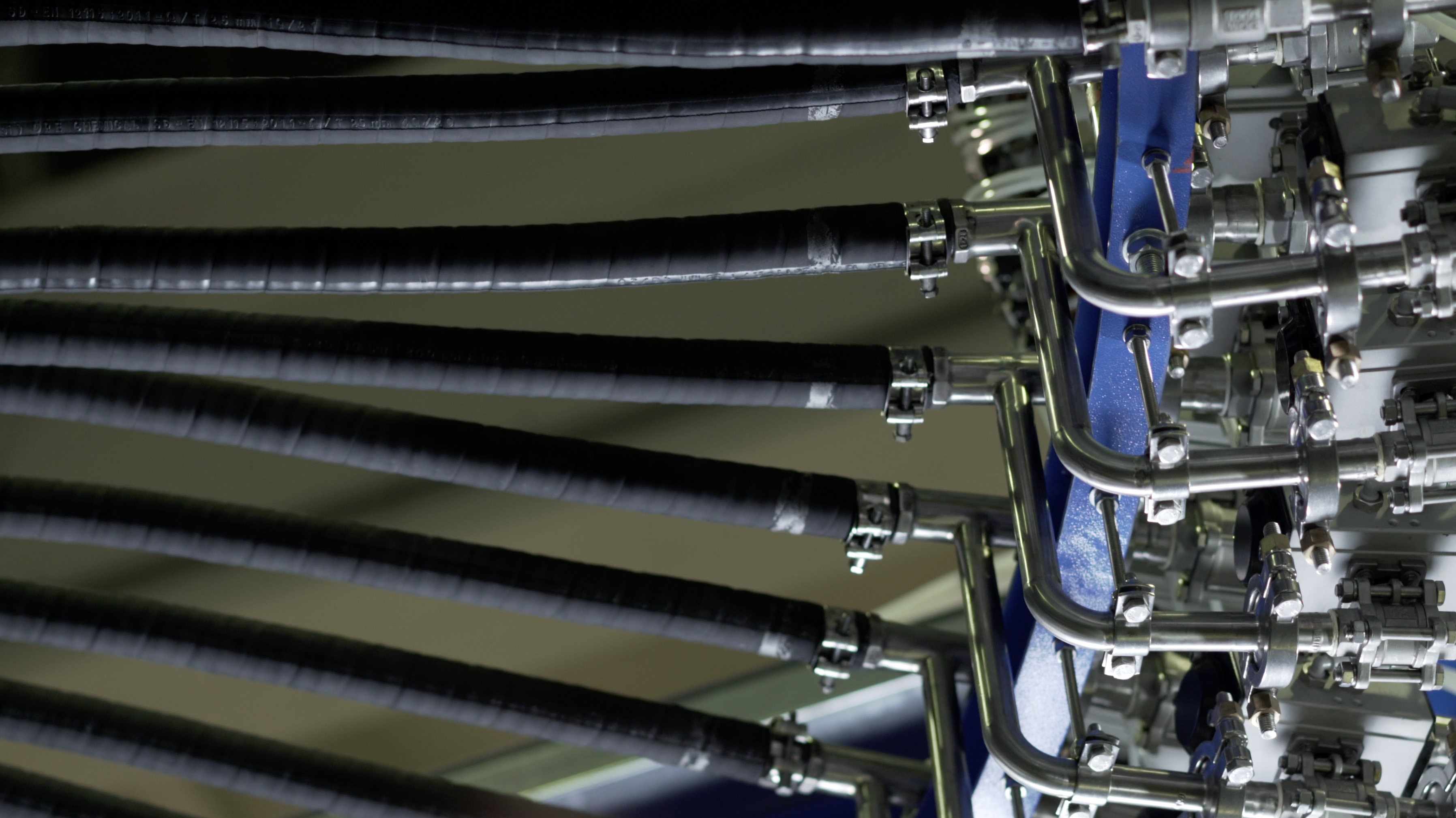

Turin, Italy, 28 Nov 2024. IM GROUP has unveiled two new customised hoses made from UPE (Ultra High Molecular Weight Polyethylene), developed specifically for its dispensing division, Inkmaker. This innovation addresses performance concerns with EPDM hoses while showcasing IM GROUP’s commitment to delivering cutting-edge, high-performance solutions for industrial applications.

The hoses, created in collaboration with a global leader in hose manufacturing, are designed to meet the precise demands of Inkmaker systems. They have undergone stringent testing, including chemical resistance to solvents like MEK (methyl ethyl ketone)—one of the most aggressive solvents, even though it is rarely present in ink and paint formulations—and conductivity compliance, ensuring reliability across challenging environments.

Christophe Rizzo, CEO EMEA/Americas, IM GROUP explains the new customised UPE hoses developed by IM GROUP’s dispensing brand, Inkmaker

Two Bespoke Variants Tailored for Industrial Needs:

-

2-Layer Hose:

Designed for static installations, this variant ensures superior chemical resistance, making it ideal for general circuits.

-

4-Layer Hose:

Engineered for flexibility and higher resistance, it is optimised for movable installations such as dispensing heads.

Both hoses feature an external protective layer made from black EPDM, providing resistance to abrasion, ozone, and fire. Additionally, the hoses are fully compliant to ATEX/Ex requirements for installation in Explosive Environment, being anti-static with surface resistance below 1 MΩ (<106 Ω) and internal resistance below 1 GΩ (<109 Ω), according to the relevant standards TR 60079-32-1:2015 'Electrostatic Hazards – Guidance' and EN 12115:2021 'Rubber and thermoplastics hoses and hose assemblies for liquid or gaseous chemicals – Specification'.

Performance Highlights:

- SD Type: Suitable for suction and delivery in positive and negative pressure systems.

- Pressure Ratings: 16 bars Standard Operating Pressure, 64 bars Explosion Pressure for the 2-layer and 48 bars Explosion Pressure for the 4-layer, where Inkmaker systems typically operate at around 6 bars.

“Our priority was to develop solutions that combine chemical resistance, electric conductivity, and flexibility, ensuring performance in the most demanding industrial environments,” said Christophe Rizzo, CEO EMEA/Americas, IM GROUP.

Advancing Innovation in Dispensing Technology

IM GROUP continues to lead the way in technological innovation, delivering customised solutions that exceed industry standards and improve operational efficiency.

About Inkmaker Worldwide

Inkmaker, is the founder of IM GROUP. Established in Turin, Italy in 1987, it is a global manufacturer of integrated dispensing systems designed to enhance efficiency by automating the precise dispensing and mixing of inks, paints, and chemicals. Inkmaker’s proprietary software and systems, manufactured across three continents, deliver consistently accurate colours, instantly and reliably. With operations in over 15 countries across 5 continents, Inkmaker ensures local expertise on a global scale. Visit Inkmaker.com.

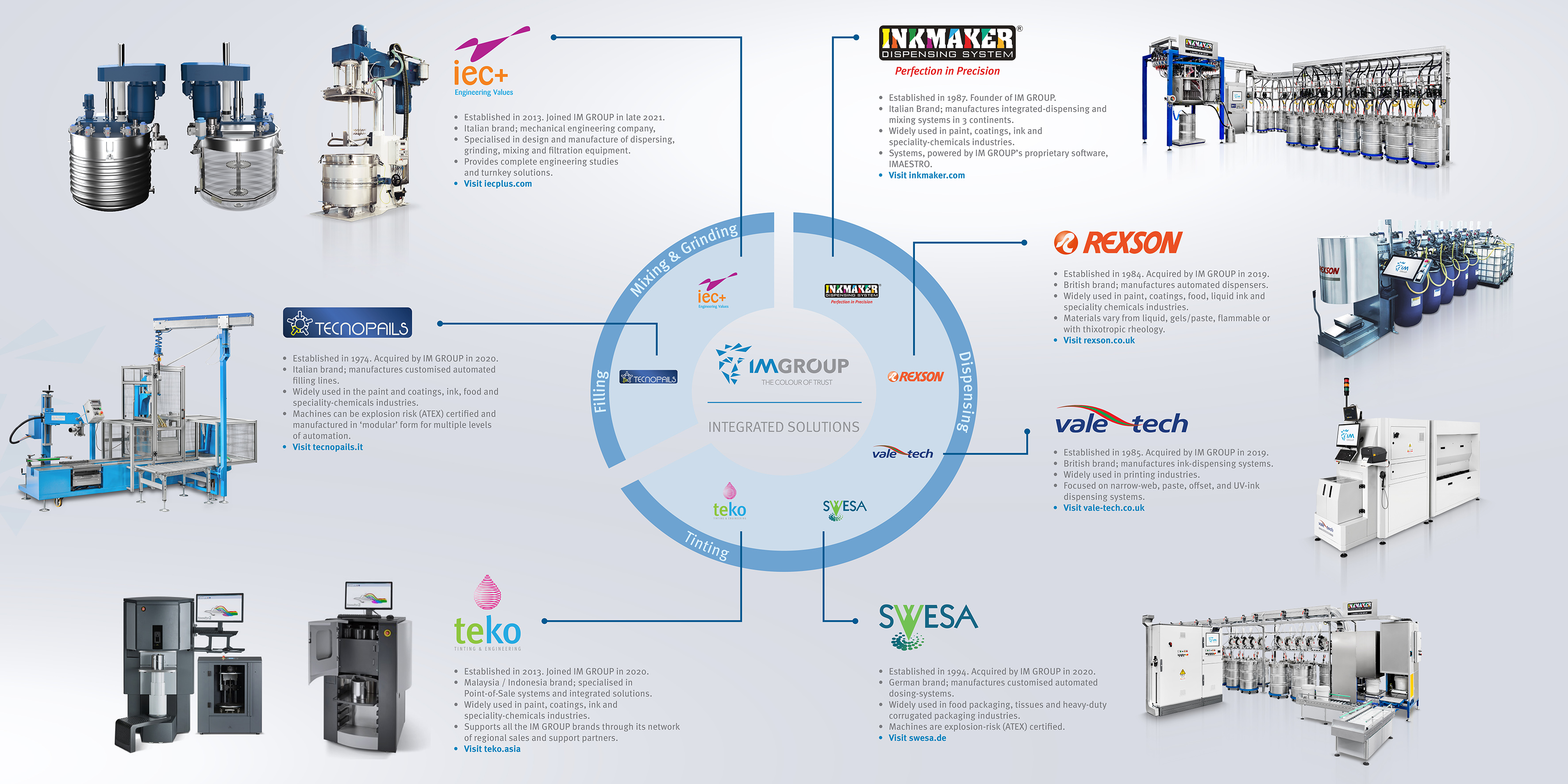

About IM GROUP

Founded in Turin, Italy, on 22 April 2021, IM GROUP is a global leader in technology and integrated engineering solutions, uniting the expertise of its brands; Inkmaker, Rexson, Vale-tech, Swesa, Teko, Tecnopails, and IEC+. The group delivers comprehensive engineering solutions through its two divisions: the Dispensing and Tinting Division and the Filling, Mixing, and Grinding Division, serving diverse industries such as paint, coatings, ink, chemicals, adhesives, pharmaceuticals, and cosmetics. With a presence in 15 countries across five continents, IM GROUP is a trusted partner to Fortune 500 companies, including Boeing, Sherwin Williams, PPG, Akzo Nobel, Avery Denison, International Paper, and Tetra Pak.

To learn more about IM GROUP and its innovative solutions, contact us at IM GROUP

Follow us on LinkedIn

_IEC.png)

IM GROUP Introduces Customised UPE Hoses for Advanced Dispensing Applications

Dec 02 2024