The PICCOLO by Inkmaker: compact, fully-automatic ink dispensing solution

How Can Manufacturers Reduce Dosing Errors, Colour Inconsistencies, and Waste with the Piccolo by Inkmaker?

Are manual weighing errors, inconsistent colours, and excessive material waste affecting your ink or coating production efficiency and profitability? The Piccolo, developed by Inkmaker—founder of IM GROUP—is a compact, fully automatic ink dispensing system designed to address these industry challenges. It combines precision dosing technology, flexible configuration, and advanced automation to improve speed, accuracy, and traceable production while reducing manual handling.

Achieve High-Precision Dosing for Consistent, Repeatable Production

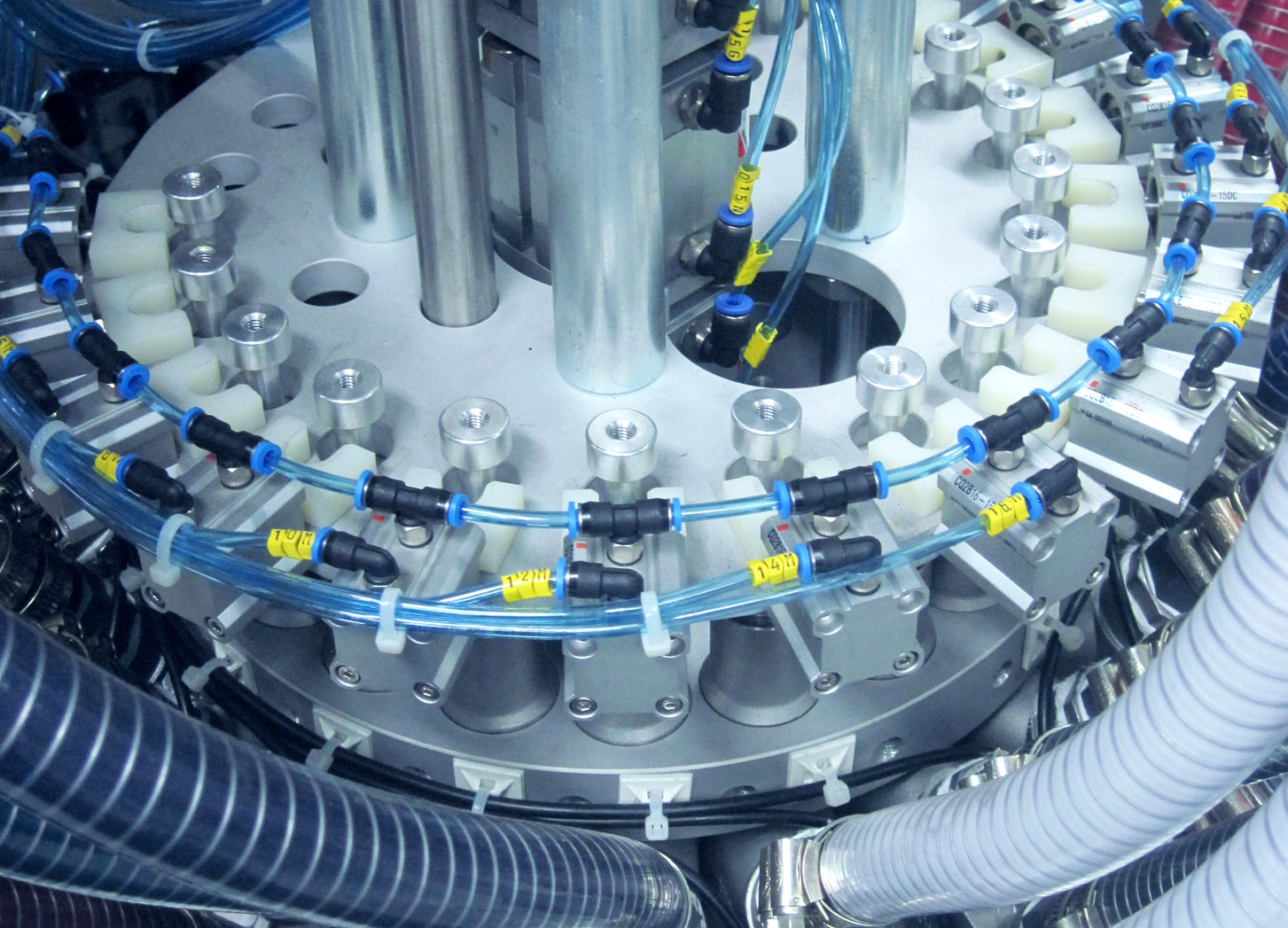

The Piccolo accommodates up to 21 multi-stage dispensing valves for precise dosing of inks, coatings, and other raw materials. Components can be stored in 200-litre drums, IBCs, or other containers and delivered directly to the dispensing head via an integrated piping network. A stainless-steel dripping pan efficiently collects washing liquid, maintaining a clean and safe workspace.

At the core of the Piccolo is a high-precision electronic scale. Valves are controlled by IMAESTRO, IM GROUP’s proprietary self-calibrating software, ensuring formula accuracy, repeatability, and production speed. Production traceability is enhanced through barcode and QR-code systems, integrated with the IMAESTRO Mobile App for smart device management.

Technical Specifications for Optimised Ink Dispensing

-

Maximum Valves: 21 Multi-Stage + 3 On/Off

-

Dispensing Precision: ±0.1 g (Optional)

-

Scale Capacity: 30 Kg ±1 g

-

Viscosity Range: ≤ 8,000 cP

-

Valve Diameter: 18 Mm With 3+ Pulsation Stages

-

Average Dosing Time for 20 Kg, 4-Component Batch: 3 Minutes

-

Optional Integration With Raw-Material Mixers and Automatic Conveyors

-

Certifications: CE, ATEX II 2 G, IECEx

These specifications enable manufacturers to achieve consistent batch quality, reduced human error, and measurable productivity improvements.

How the Piccolo Resolves Key Industry Challenges

The Piccolo addresses the most common challenges in ink and coating production:

-

Manual Weighing Errors

-

Inconsistent Colours or Batch Variations

-

Excess Material Waste and Operational Inefficiencies

By applying “Right-First-Time,” “Just-In-Time,” and “Just-Enough” Production Principles, supported by IMAESTRO software, the Piccolo ensures fast, accurate, and repeatable dosing. This reduces rework, minimises overproduction, and prevents unnecessary quality checks, improving cost efficiency and overall productivity.

Operational Advantages for Modern Manufacturing

-

Suitable for Water-Based and Solvent-Based Inks and Coatings

-

Self-Adjusting Dispensing Parameters for Consistent Formula Reproduction

-

Reduction of Waste by Reusing Leftover Materials in Future Batches

-

Compact Footprint With Manual Sliding Platform for Pail Handling

-

Improved Safety, Cleanliness, and Ergonomics

-

Seamless Stock Management, Auditing, and Batch Cost Evaluation

-

ERP/MRP Integration for Full CIM-CAM Production

-

Compatible With All Major Spectrophotometer Brands

-

ISO-Standard Product Management and Traceable Production Records

-

Password-Protected Formula Database With Automated Backups

-

Over 100 KPI-Focused Production Reports for Operational Insight

Why the Piccolo Is the Optimal Automatic Ink Dispensing Solution

The Piccolo is a precise, flexible, and reliable solution for manufacturers seeking improved accuracy, reduced waste, and optimised production efficiency. By combining advanced hardware, intelligent software, and certified safety features, the Piccolo supports modern ink and coating operations while delivering rapid return on investment.

This article is based on the original piece published in Japanese in Convertech magazine.

Frequently Asked Questions About the Piccolo by Inkmaker

Q: What Is the Piccolo by Inkmaker?

A: The Piccolo is a compact, fully automatic ink dispensing system designed for moderate to high-volume manufacturing. It combines precision dosing, flexible configuration, and automation to ensure accurate, repeatable production.

Q: How Many Dispensing Valves Does the Piccolo Support?

A: The system supports up to 21 multi-stage dispensing valves and 3 on/off valves, allowing precise dosing of inks, coatings, and other raw materials.

Q: What Is the Dosing Precision of the Piccolo?

A: The Piccolo can achieve a dosing precision of ±0.1 g with optional high-precision scaling.

Q: Which Software Controls the Piccolo?

A: The Piccolo is controlled by IMAESTRO, IM GROUP’s proprietary self-calibrating software, ensuring formula accuracy, repeatability, and speed.

Q: What Materials Is the Piccolo Compatible With?

A: The Piccolo is suitable for water-based and solvent-based inks and coatings and can integrate with mixers, conveyors, and ERP/MRP systems.

Q: What Certifications Does the Piccolo Have?

A: The Piccolo is certified with CE, ATEX II 2 G, and IECEx.

Q: How Does the Piccolo Reduce Waste?

A: By applying “Right-First-Time,” “Just-In-Time,” and “Just-Enough” Production Principles and reusing leftover materials, the Piccolo minimises overproduction and errors.

To learn more about how the Piccolo can streamline your production, Contact Us today.

EDITOR NOTES

Silvio Cimenti – Global Director of Branding and Marcom, IM GROUP

scimenti@im-group.com

im-group.com

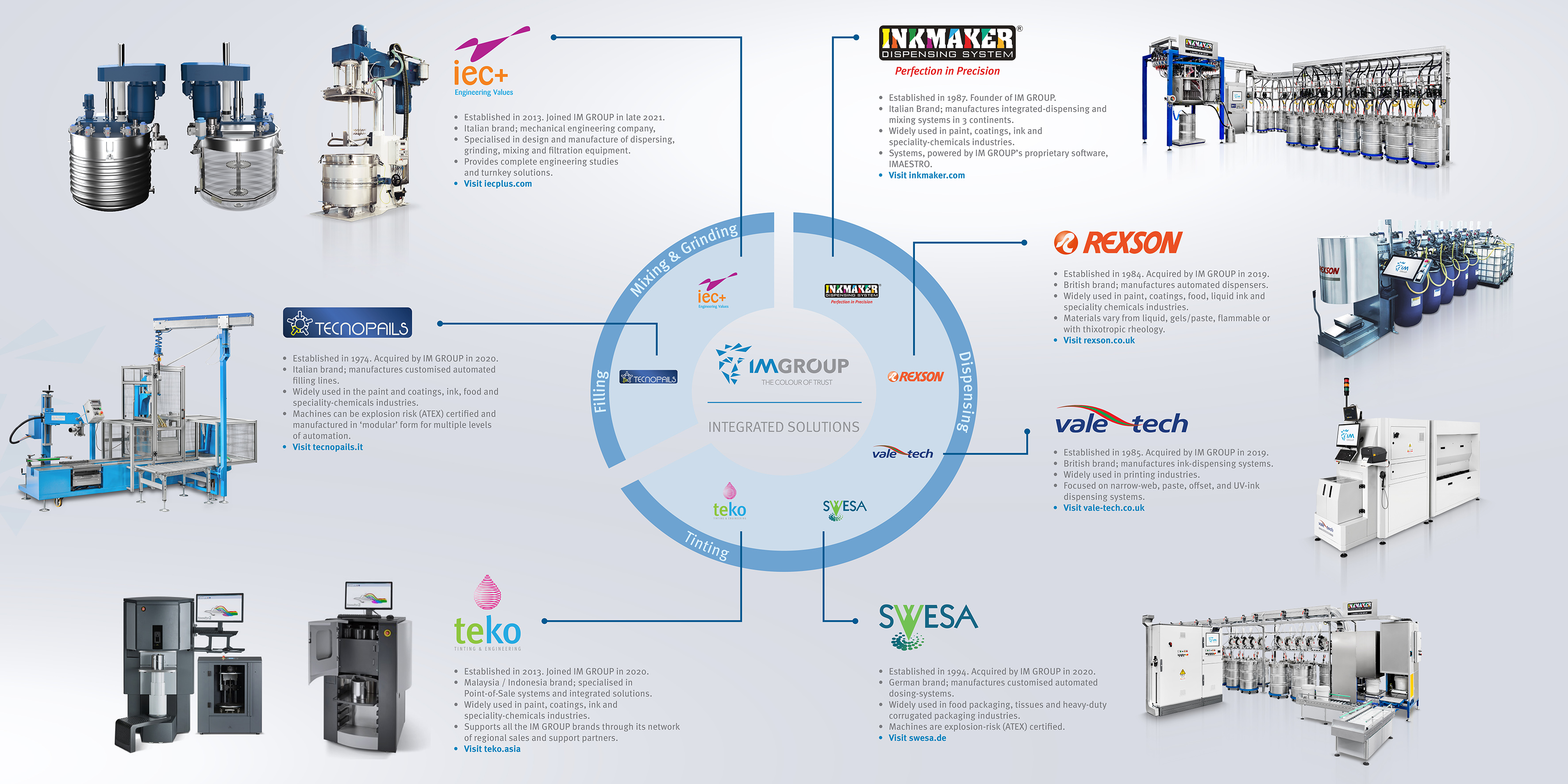

About IM GROUP

Founded in Turin, Italy, on 22 April 2021, IM GROUP is a global leader in technology and integrated engineering solutions, uniting the expertise of its brands; Inkmaker, Rexson, Vale-tech, Swesa, Teko, Tecnopails, and IEC+. The group delivers comprehensive engineering solutions through its two divisions: the Dispensing and Tinting Division and the Filling, Mixing, and Grinding Division, serving diverse industries such as paint, coatings, ink, chemicals, adhesives, pharmaceuticals, and cosmetics. With a presence in 15 countries across five continents, IM GROUP is a trusted partner to Fortune 500 companies, including Boeing, Sherwin Williams, PPG, Akzo Nobel, Avery Denison, International Paper, and Tetra Pak.

To learn more about IM GROUP and its innovative solutions, visit: im-group.com or contact us at IM GROUP

Follow us on LinkedIn.

INKMAKER RECOGNISED AT OFFICIAL OPENING OF DIC’S NEW INK MANUFACTURING FACILITY

Oct 23 2025